Common Causes Of Offshore Jacking System Failures

Predictive Maintenance Solutions With SMEC Automation

Failures Aren’t Sudden — They’re Silent. Here’s How to Stop Them!

In offshore , jacking systems are the backbone of rig mobility and stability. When they fail, the consequences can be catastrophic – delayed operations, million-dollar losses, or worse, structural damage that threatens the entire rig.

As offshore assets age and operational demands intensifies in the coming years, understanding why jacking systems fail offshore — and how to prevent it — is no longer optional. It’s mission-critical.

1. Mechanical Fatigue and Wear

Jacking systems endure thousands of lifting, lowering, and station-keeping cycles. Over time, mechanical stress leads to:

- Pinion and rack wear

- Rack misalignments

- Loosening of structural bolts

Unchecked, these degradations snowball into major failures, often under peak load conditions.

2. Hydraulic System Failures

Hydraulic cylinders are the heart of lifting operations. Common issues include:

- Internal seal wear and scoring

- Hydraulic fluid contamination

- Loss of hydraulic pressure

Pressure loss can mean sudden loss of lifting control — a critical risk during heavy seas.

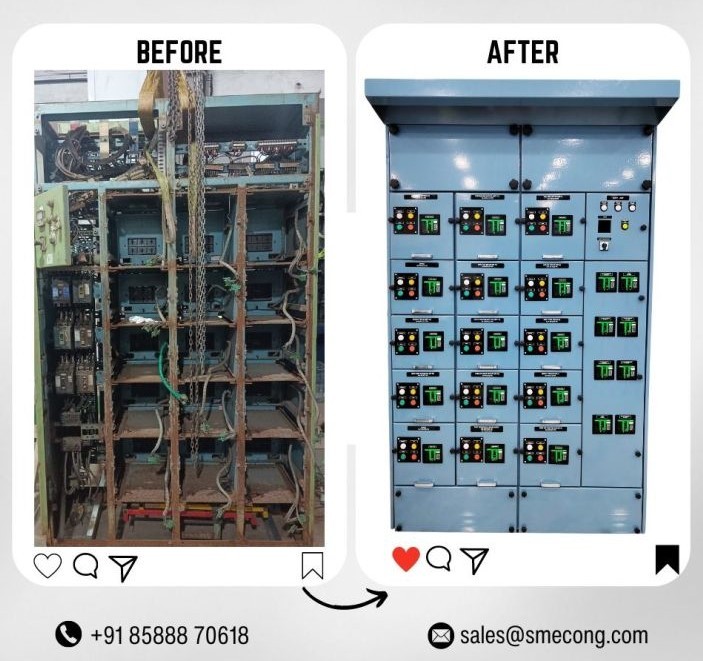

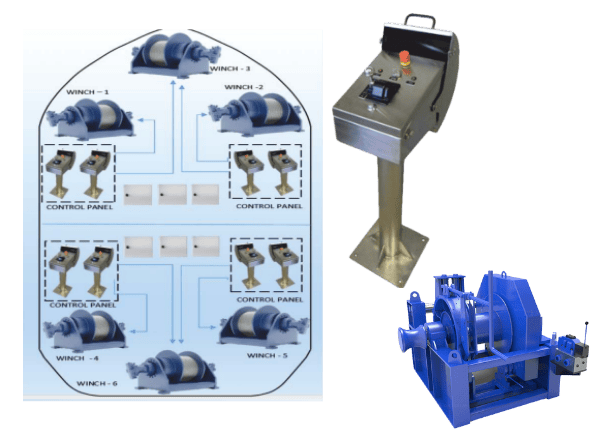

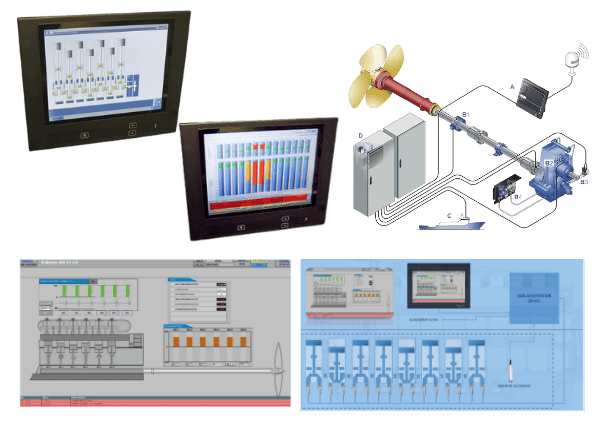

3. Electrical and Automation Faults

Modern jacking systems rely on PLC-controlled motors and sensors. Without preventive maintenance, electrical failures emerge:

- Motor winding breakdowns

- Limit switch malfunctions

- PLC relay faults

One unnoticed fault can halt rig operations instantly.

4. Corrosion and Environmental Damage

Offshore environments are brutal:

- Saltwater corrosion thins jacking legs

- Structural degradation weakens safety margins

- Rack and pinion systems deteriorate faster than expected

Without proactive anti-corrosion strategies, hidden structural risks accumulate.

5. Lack of Preventive Inspection and Maintenance

Visual inspections miss up to 70% of developing faults (Source: Offshore Maintenance Journal, 2024). Without structured condition monitoring, failure often strikes without warning.

How to Prevent Offshore Jacking System Failures

1. Implement Regular Condition Monitoring

Leverage:

- Vibration analysis

- Thermal imaging

- Oil sampling diagnostics

Bonus: Real-time remote monitoring solutions like SMEC’s NexWave detect early faults long before traditional inspections would.

2. Perform Hydraulic System Audits

- Inspect seals, cylinders, filters, and fluid quality regularly

- Track internal leakage or pressure loss proactively

Hydraulic health = Lifting safety.

3. Maintain Electrical and Automation Systems

- Check motor currents and insulation resistance

- Test relay response times.

- Update PLC firmware and secure systems against cyber threats

4. Strengthen Corrosion Protection Programs

- Annual coating inspections and reapplications

- Offshore-grade anti-corrosion treatment

- Scheduled upgrades of cathodic protection systems

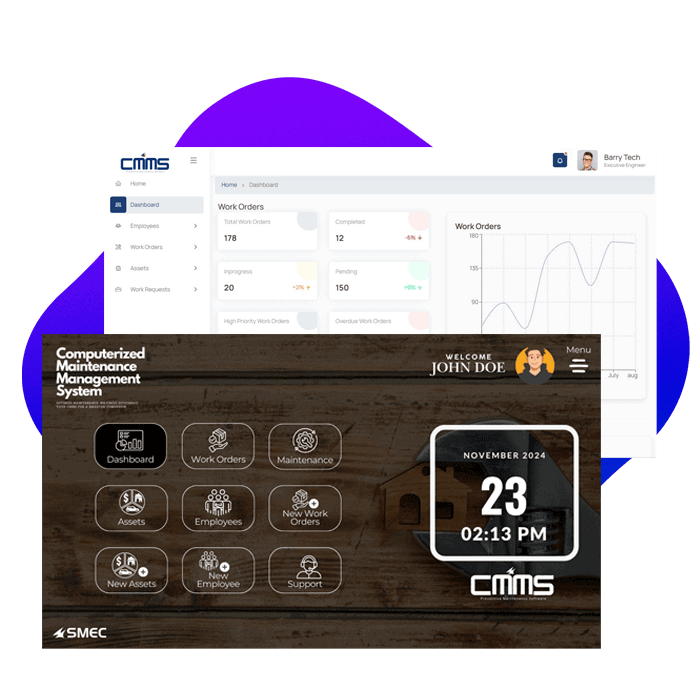

5. Partner with Expert AMC Providers

Securing an Annual Maintenance Contract (AMC) with specialized service providers ensures:

- Predictable service schedules

- Proactive fault detection

- Lifecycle cost reductions

- Greater operational peace of mind

SMEC Automation delivers customized AMC programs for jacking systems, trusted by global offshore operators.

Real-World Success Story: Saving a Middle East Jack-Up Rig

In 2024, SMEC Automation was called to assist a Middle East jack-up facing critical jacking delays. Our predictive maintenance approach detected hidden pinion wear — invisible to standard inspections.

Outcome:

- Emergency retrofit avoided

- 7 days of downtime saved

- Over $700,000 in operational cost savings

The Bottom Line: Predict, Protect, Perform

Jacking system failures are not inevitable — they are preventable.

Operators who invest in predictive strategies, disciplined maintenance, and expert partnerships today are the ones who will secure their offshore assets, safety, and profitability well into the next decade.

Start Securing Your Jacking Systems with SMEC! [ SMEC Automation ]

📩 Contact us: sales@smecong.com | 🌐 Visit: www.smecoilandgas.com | 📞 +91 85888 70618

Happy Reading!

#OffshoreMaintenance #JackingSystems #MarineEngineering #PredictiveMaintenance #AssetIntegrity #OilAndGasIndustry #FleetReliability #SMECAutomation

ADDRESS: 2nd FLOOR KALOOR COMPLEX,COCHIN

PHONE NUMBER: +91 70453 55414

EMAIL: support@smec.in

WEBSITE: www.smec.in